HISTORY OF BBC / ABB - BADEN AND OF TURBOCHARGING

The engineering company BBC, Brown Boveri & Cie. in Baden (about 18 km north west of Zürich) was founded on 2nd. October 1891 by the two engineers Walter Boveri und Charles E.L. Brown and developed rapidly into one of the most important enterprises of Switzerland, see also www.abb.ch

Walter Boveri (1865-1924) was a German immigrant and his partner Charles E.L Brown (1863-1924) was the son of a British engineer in Winterthur (co-founder of SLM, Schweiz. Lokomotiv- und Maschinenfabrik, Winterthur). The two founders made their acquaintance during their time with Maschinenfabrik Oerlikon and from about 1888 they were busy with the planning and setting up of an own electrical engineering company.

At first the company produced electrical machines and plants, but from 1900 onwards BBC was rapidly developing into a large international engineering group. The first foreign subsidiary companies were founded, 1900 in Germany, 1901 in France, 1903 in Italy, as well as in many other countries in Europe.

After the 2nd. World War BBC expanded also to overseas countries and became a real global engineering company. In the year 1988 BBC amalgamated with ASEA in Sweden, another leading company in the field of electrical engineering and a new group emerged ABB, Asea Brown Boveri with its head office in Zürich.

In the year 1900 the company also commenced with the development and the production of steam turbines. Apparently also some steam turbines for the maritime shipping industry were produced, but the largest part of these plants were produced for electrical power stations and industrial applications. According to our information, the works in Baden fabricated in 1941 a set of steam turbines of 70'000 HP for the Soviet battle ship SOVETSKIY SOYUZ (293 m long, 9 x 40.6 cm guns and 80'000 tons displacement).

The battle shipwas never completed and it is not known what happened to

the steam turbines

On many ships alternators and electrical motors, made by BBC, as well as by ASEA were in operation, today these machines, plus many other products are offered from ABB factories abroad. These include complete systems for electrical power generation and distribution, electrical ship's propulsion, such as the newly developed azipod-drives and CRP-azipods (CRP = Contra Rotating Propellers), just to name a few of the most important products, see also www.abb.com/marine

The probably most important and best known product used in maritime shipping and inland navigation, is the turbocharger for diesel engines, its history became a 100 years old in 2005.

The principle of turbocharging increases the power of a diesel engine by pressing additional combustion air into the cylinders. In general we can say, a turbocharger consists of a turbine and a compressor, mounted on a common shaft in a casing. The turbine exploits the considerable remaining heat of the exhaust gases and drives the compressor. The compressor draws in fresh air and pushes the air with pressure into the cylinders of the diesel engine. Thus more fuel can be injected and burnt, which results in a higher power output.

Alfred Büchi (1879-1959), an engineer working with Sulzer Brothers AG in Winterthur applied in 1905 for his first patent for turbocharging. It was a long way, and probably also a very stony one, until the first turbocharger was constructed. After further studies on the subject, Alfred Büchi obtained in 1915 a further patent, the so called "Spülpatent" (literally "scavenging patent"), his most important patent on the subject of turbocharging. In the same year he established his first contact with BBC to find a way for cooperation, but an agreement was concluded only in 1923.

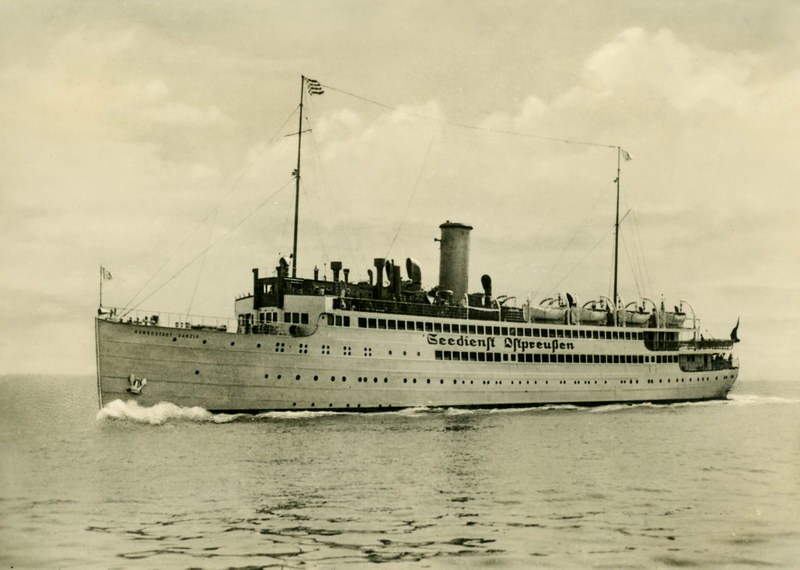

At the same time the Vulkan-Werft (Vulkan Shipyard) in Stettin (today the polish city of Szczecin) received the building contract to construct two passenger vessels for the shipping company "Seedienst Ostpreussen". These two ships, the HANSESTADT DANZIG and the PREUSSEN were each equipped with two MAN built diesel engines and for the first time turbocharging was applied. The turbochargers were constructed in the Vulkan-works in Hannover, under the supervision of Alfred Büchi and the compressor wheels were fabricated by BBC, Mannheim. These were the very first motor vessels using supercharged diesel engines.

HANSESTADT DANZIG

Photosource: © Wolfgang Kramer coll., Rostock

PREUSSEN

Photosource: © Wolfgang Kramer coll., Rostock

In the year 1926 a new company was founded, named "Büchi Syndikat" to further develop turbocharging. Alfred Büchi took over the responsibilities for design and construction, BBC was entrusted with the production and SLM, Winterthur (Schweizerische Lokomotiv- und Maschinenfabrik) delivered the test engines. With the "Büchi Syndikat" new relations with many engine builders were made and the principle of turbocharging was quickly spread and applied. As from 1928 more and more motor ships were equipped with turbocharged

engines.

Freight / Passengership (408

passengers, 20 knots)

DON ISIDRO of De la Rama Steam Ship Co., Iloilo Philippines built 1939 at

Fried. Krupp Germaniawerft AG - Kiel, at the Kiel Fjord

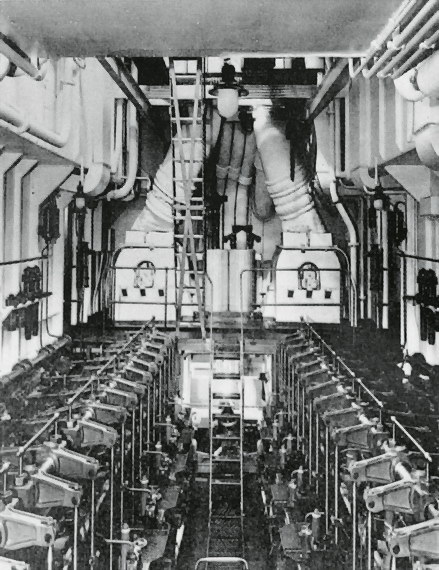

Engine-room of the DON ISIDRO

Photosource: ABB - Baden

The real breakthrough of turbocharging followed after the 2nd. World War with the development and introduction of the turbocharger of the type VTR, which will be remembered by many older marine engineers.

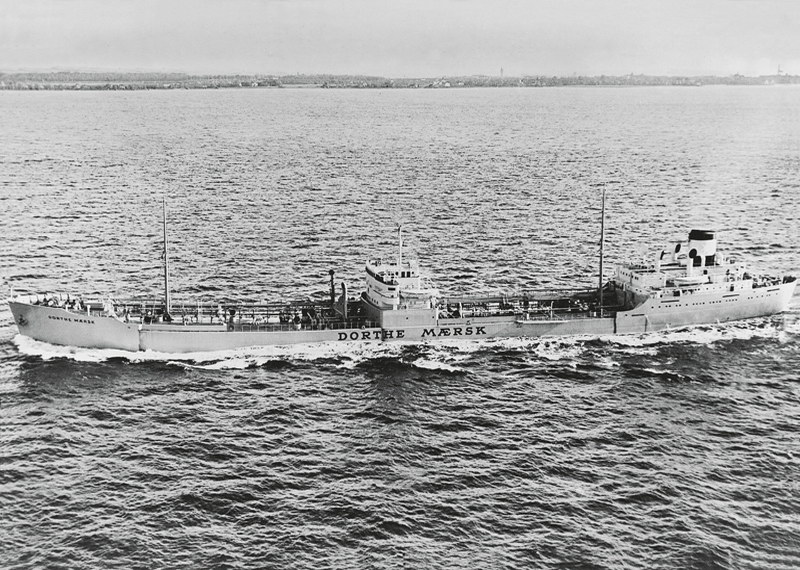

Initially turbocharging was employed for 4 stroke diesel engines, but in 1934 the development of turbocharging for 2 stroke engines was taken up in cooperation with Sulzer Brothers in Winterthur. However, it lasted until 1952 until the first application in maritime shipping took place with the tanker DORTHE MAERSK (18,000 DWT) entering service. The ship was furnished with one 2-stroke, 6-cylinder, turbocharged main engine, made by Burmeister & Wain A/S, Copenhagen. The two VTR-630 turbochargers improved the power output from original 5,530 BHP to 8,000 BHP.

Photosource: ABB - Baden

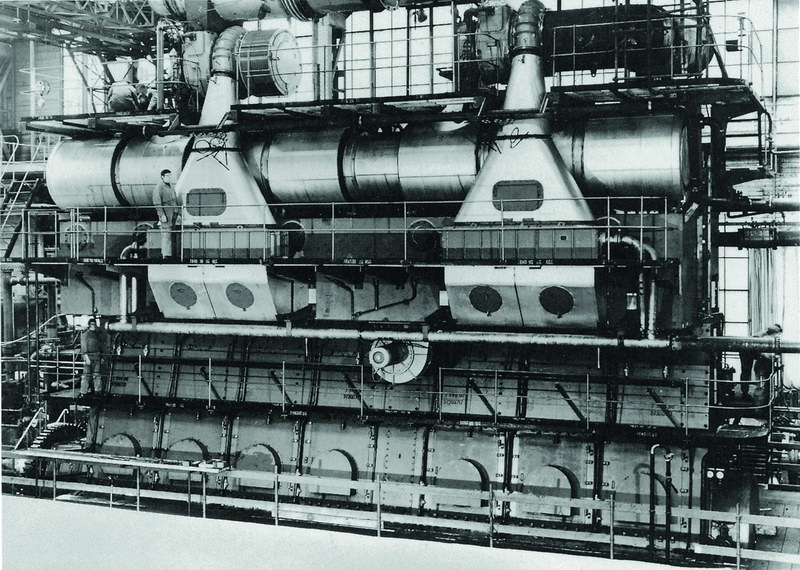

Photosource: ABB - Baden

In the early 1990ties ABB developed a completely new generation of turbochargers, the TPS series for smaller engines up to 3000 kW power output and the TPL series for large engines from 2500 kW upwards. Through the development of new, more efficient diesel engines, also turbochargers had to be adapted to the new demands and today they work with much higher pressures and efficiencies. A new challenge is also the stipulation of reduced emission values by governments and other international organizations for new diesel engines. Generally turbochargers have become lighter and more compact in relation to their power and thanks to new construction materials the water cooling could be eliminated. The roller bearings of the VTR-chargers were replaced by plain bearings, lubricated and cooled by the oil from the engine's main lubrication system. For further technical information, please refer to: www.abb.com/turbocharging

Today the turbochargers are still designed and produced by ABB Turbo Systems Ltd., Baden, Switzerland. In a new, well equipped test stand the turbochargers can be tested under actual operating conditions and experiments can be conducted. The offices and the modern workshops are located inside the site of the old BBC factory. A tight net of more then 100 service stations in 55 countries ensures a worldwide service for spare parts, as well as for overhaul and repair jobs

Photosource: ABB - Baden

Photosource: ABB - Baden

Further information:

- Brochure "A Century of

Turbocharging"

- Book of Ernst Jenny "Der BBC-Turbolader – Geschichte eines Schweizer Erfolges"

SwissShips March 15, 2009

|

![]()